Products

Chromium Metal

Chromium is widely used for alloying steel and its alloys to give them corrosion and heat resistance. The most famous ball-bearing steels (about 1% Cr and 1% C), stainless steels (18% Cr and 8-10% Ni), resistance alloys - nichromes (60-80% Ni, 15-20% Cr) and heat resistance alloys (13-16% Cr) based on iron, nickel and cobalt.The practical experience shows that the addition of chrome to steel leads to the following: - reduced grain size - increased hardenability - improved hardness and strength - improved ductility when chrome contents <1 % - low influence on oxidation resistance at high temperatures - improved strength at high temperatures

The presence of chromium in carbon steels improves their hardness and wear resistance.

Chromium alloyed cast irons are widely used.

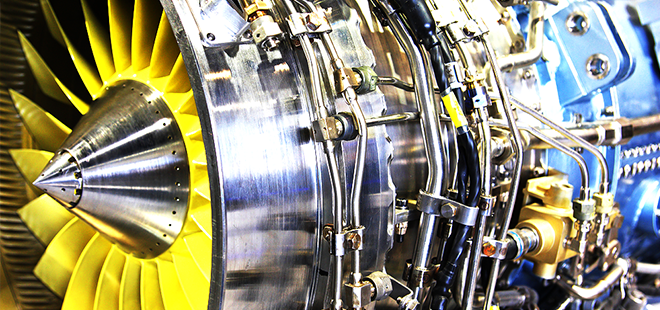

High-temperature steels and alloys containing 13-60% Cr are used for making gas turbines and jet engines.

Chrome plating of metal products, i.e. electrochemical coating by a thin film of chromium, leads to their improved durability and service life.

Chemical composition:

| Марка | Химический состав,% | |||||||

| Cr | Si | Al | Fe | C | S | P | Cu | |

| X99H1 | 99,0 | 0,2 | 0,5 | 0,5 | 0,01 | 0,02 | 0,005 | 0,005 |

| X99H2 | 99,0 | 0,2 | 0,5 | 0,5 | 0,03 | 0,02 | 0,01 | 0,008 |

| X99H4 | 99,0 | 0,2* | 0,5 | 0,5 | 0,03 | 0,02 | 0,02 | 0,01 |

| X99H5 | 99,0 | 0,2 | 0,5 | 0,5 | 0,03 | 0,02 | 0,02 | 0,01 |

| X99 | 99,0 | 0,2 | 0,5 | 0,5 | 0,03 | 0,02 | 0,02 | 0,02 |

| X98,5 | 98,5 | 0,4 | 0,7 | 0,6 | 0,03 | 0,02 | 0,02 | 0,02 |

Chrome is crushed to lumps of not more than 10 kg. The amount of fines passing through the sieve with mesh dimensions 10x10 mm, does not exceed 10% of the batch mass. Supplied in steel drums up to 300kg. The surface of the lumps has no distinct inclusions of slag, refractory materials and other foreign matter.

Density 7.53 g/cm3

Melting point 1830-1870 оС